Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

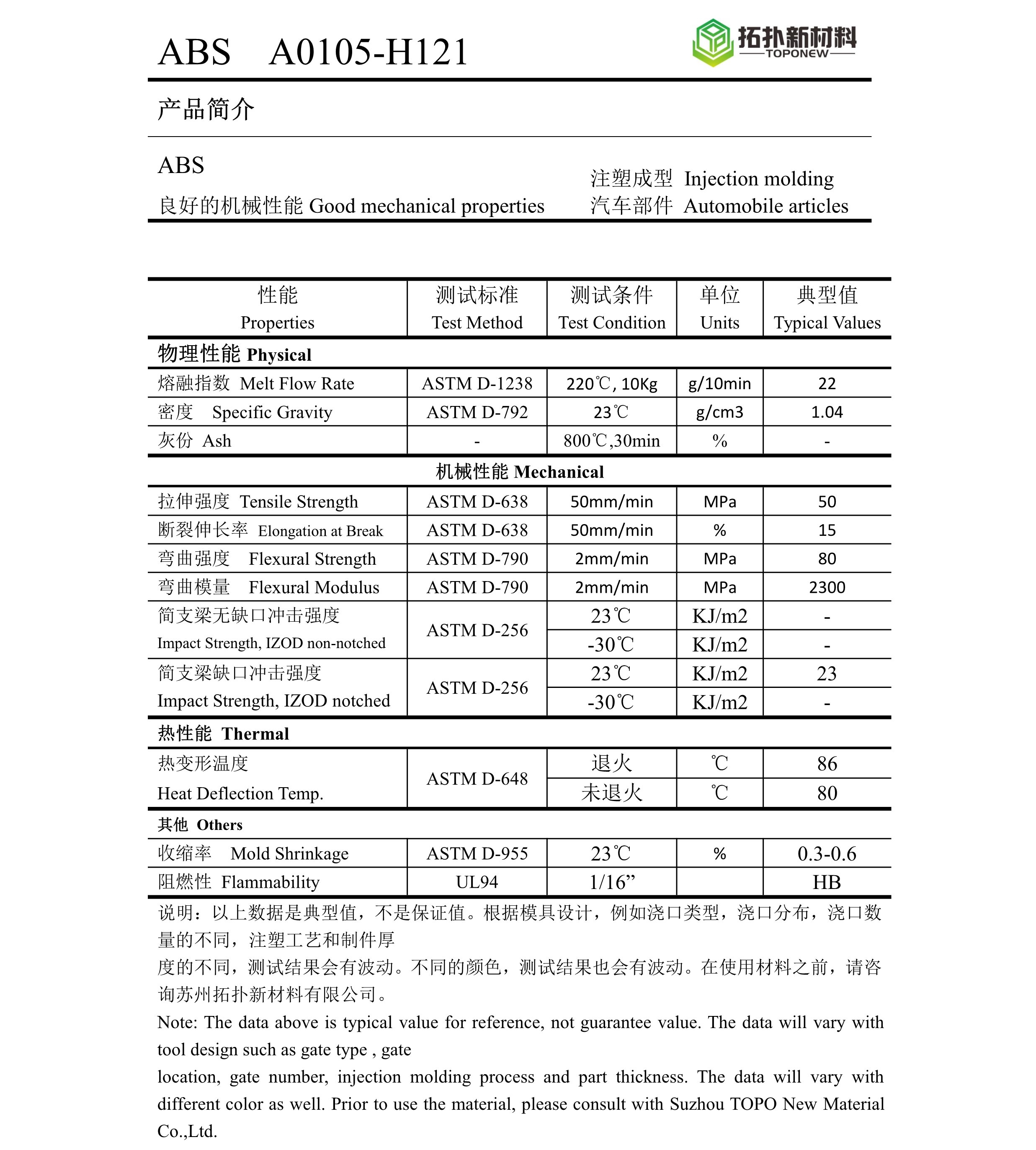

ABS A0105-H121

MI: 22 g/10min

UL94 1.6mm HB

(Custom materials available according to your Technical Data Sheet)

- Product Details

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials )

- Other materials can also be customized ( Just need to provide your Technical Data Sheet. )

The Technical Data Sheet of A0105-H121 ABS (abcrilonitrilo butadieno estireno)

ABS resins have a well-balanced set of properties for molding tight dimensional control articles with outstanding surface finishing, good impact resistance, and metal plating characteristics. ABS resins belong to a versatile family of thermoplastic polymers. ABS is produced by combining three monomers: acrylonitrile, butadiene, and styrene. The chemical structure of these monomers requires each monomer to be an important component of the ABS resins. Acrylonitrile contributes heat resistance, chemical resistance, and surface hardness to the system. The butadiene component contributes toughness and impact resistance, while the styrene component contributes processibility, rigidity, and strength.

The Feature of Acrylonitrile Butadiene Styrene ABS

- ABS plastic materials have good impact and heat resistance, low temperature resistance, chemical resistance, and electrical properties.

- It is also easy to process, dimensionally stable and has a good surface gloss.

The Application of ABS Granule

- Overhead luggage storage compartment: These compartments require durable materials because they are subjected to quite a bit of strain in normal use. Yet, they also need to be lightweight, because their presence does not add to the aerodynamics or operation of the aircraft. Plastics like Acrylonitrile Butadiene Styrene (ABS) are excellent materials for these bins.

- Cabin Interiors: High impact, fire-rated thermoplastic materials, and thermoplastic materials, are engineered to have the durability, cleaning chemical resistance, and fire resistance required for aircraft interiors. These materials are thermoformed and used as tray tables, armrests, and seatbacks.

ABS, short for Acrylonitrile Butadiene Styrene, is a versatile thermoplastic polymer known for its superior attributes. One of our popular offerings is our high-quality white ABS plastic pellets. These pellets feature a clean and pure color, making them ideal for various applications.

ABS resin finds extensive usage across multiple industries. Its exceptional combination of strength, toughness, and dimensional stability make it suitable for a wide range of applications. Whether it's in automotive parts, electronics, household appliances, or even toys and consumer goods, ABS resin delivers excellent performance.

At TOPONEW, we offer bulk ABS pellets, ensuring a reliable supply for manufacturers and processors alike. Our ABS plastic resin pellets are manufactured using advanced techniques, resulting in consistent quality, uniformity, and excellent processability.

Choose TOPONEW for all your ABS material needs, and experience the benefits of our top-notch white ABS plastic pellets.

For more information about ABS, please kindly contact us at any time, we are glad to answer for you. If you want to find a partner, hope that we will be your best choice.

Download

-

ABS A0105-H121.pdf

Download ABS A0105-H121.pdf